In today’s increasingly noisy environment, achieving serenity within our living and working spaces has become a priority for many. As a crucial solution to this dilemma, sound insulation foam has emerged as a game-changer in the field of acoustics. According to acoustics expert Dr. Emily Carter, “Sound insulation foam significantly minimizes sound transmission, enabling a much more peaceful atmosphere.” This innovative material not only plays a vital role in reducing unwanted noise but also enhances the overall quality of life by facilitating better concentration and relaxation.

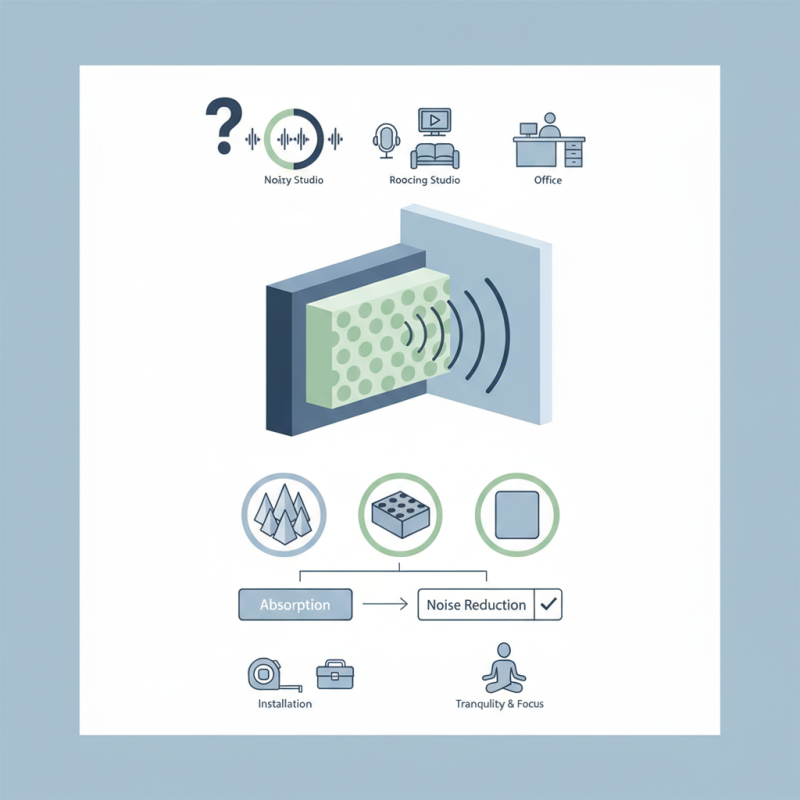

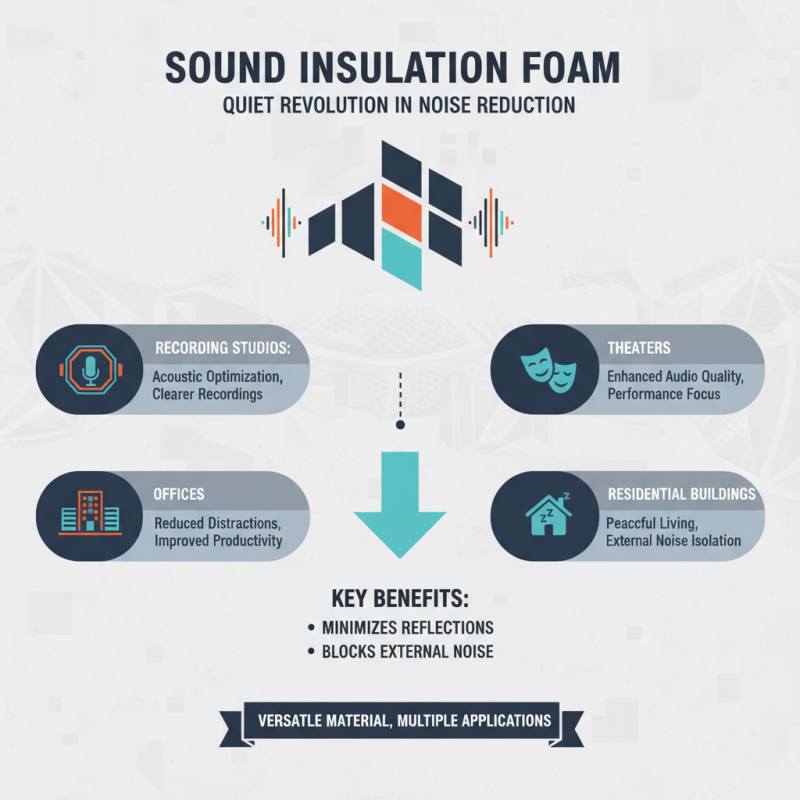

Sound insulation foam is designed to absorb sound waves, reducing echo and reverberation in both residential and commercial spaces. Its versatility makes it ideal for a wide range of applications, from recording studios to home theaters and open office layouts. By implementing sound insulation foam, individuals and businesses alike can create environments that foster productivity and tranquility, addressing the growing demand for effective noise reduction solutions in our daily lives.

In this article, we will explore the various types of sound insulation foam available in the market, how they function in mitigating noise, and the best practices for their application. As we delve into the science behind sound insulation foam, we will uncover how this remarkable material can transform spaces into havens of peace amidst the cacophony of modern life.

Sound insulation foam is a specialized material designed to absorb and reduce sound transmission in various environments. Typically composed of polyurethane or melamine, these foams are engineered to trap sound waves, minimizing their reflections and preventing them from traversing through walls, floors, and ceilings. The intricate cellular structure of sound insulation foam plays a pivotal role in its effectiveness, allowing it to dampen vibrations and lower overall noise levels.

The composition of sound insulation foam is crucial to its performance. High-density foams offer superior sound absorption capabilities, making them ideal for use in recording studios, theaters, and residential spaces requiring quieter atmospheres. Additionally, the foam’s porous nature facilitates sound wave entrapment, thus enhancing its ability to reduce reverberation. Manufacturers often design these foams with specific thickness and surface patterns to optimize their acoustic properties, ensuring users benefit from a significant reduction in unwanted noise.

Sound insulation foam is a vital component in creating quieter environments by reducing noise transmission. There are several types of sound insulation foam materials, each with distinct properties that cater to specific acoustic needs.

One common type is melamine foam, known for its excellent sound-absorbing qualities. Its open-cell structure allows it to effectively reduce mid to high-frequency noise, making it ideal for recording studios and home theaters.

Another type is polyurethane foam, which can be molded into various shapes and thicknesses, enhancing its versatility. This foam is particularly effective in absorbing sound waves and is often used in residential buildings to minimize noise pollution from within and outside.

Additionally, acoustic foam panels, typically made from either polyurethane or polyester, are designed to optimize sound quality by reducing echo and reverberation. These panels come in various textures and colors, allowing for aesthetic integration into any space. By selecting the appropriate sound insulation foam material, individuals can significantly improve their acoustical comfort and reduce unwanted noise in their environments.

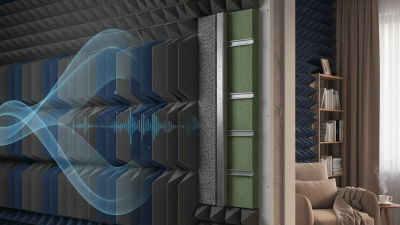

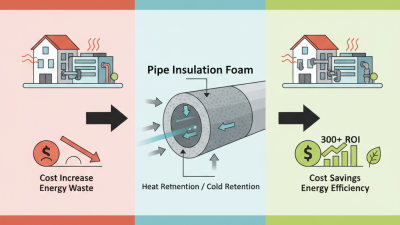

Sound insulation foam plays a crucial role in enhancing noise reduction by effectively absorbing sound waves. Its design, typically comprised of open-cell or closed-cell structures, allows it to harness specific acoustic properties to dampen vibrations. According to a report from the Acoustical Society of America, sound insulation foam can reduce noise levels by up to 25 decibels in certain applications, making it invaluable in both residential and commercial settings.

The mechanism by which sound waves are absorbed involves several factors. When sound waves travel, they encounter the porous surface of the foam, which disrupts their path, allowing the energy from these waves to be dissipated as heat rather than reflecting back into the environment.

Studies indicate that foam with larger, open cells tends to be more effective at lower frequencies, while denser closed-cell foams are better suited for higher frequencies. This duality in application underscores the importance of selecting the right type of foam based on the specific noise environment, ultimately leading to superior noise control outcomes.

Sound insulation foam plays a crucial role in various applications across different settings, contributing significantly to noise reduction. This versatile material is widely used in environments like recording studios, theaters, offices, and residential buildings. In recording studios, for instance, sound insulation foam is essential for creating an acoustically optimized space, minimizing sound reflections and external noise interference, allowing for clearer recordings. Similarly, in theaters, the use of sound insulation foam enhances sound quality, ensuring that performances are experienced without unwanted noise disruptions.

The increasing demand for sound insulation foam is reflected in the robust growth projected for the sound insulation market. According to recent forecasts, the market is expected to grow from $15.09 billion in 2024 to $25 billion by 2035, with a compound annual growth rate of around 4.7% during the forecast period. This trend underscores the expanding applications of sound insulation materials in industries such as automotive, HVAC, and construction. As noise pollution becomes a more pressing issue, the adoption of sound insulation solutions will continue to be a key focus for various sectors, enhancing both comfort and productivity in different environments.

Sound insulation foam is an effective solution for improving noise reduction in various environments, from residential properties to commercial spaces. According to a report by the Acoustical Society of America, using sound insulation materials can reduce noise levels by up to 50%, making spaces significantly quieter and more comfortable. This is particularly beneficial in noisy urban areas or within multifunctional buildings where sound intrusion can lead to decreased productivity and increased stress.

One of the primary benefits of sound insulation foam is its ability to dampen sound waves, resulting in a marked improvement in sound privacy. With a density that absorbs and stops sound transmission, these foams provide a versatile application, whether in home theaters, music studios, or in office cubicles. Further studies indicate that spaces fitted with proper sound insulation can enhance concentration levels by up to 60%, showcasing the profound impact of a quieter environment on cognitive function.

Tips for maximizing the effectiveness of sound insulation foam include ensuring proper installation and covering all potential sound leak points, such as windows and doors. Additionally, combining foam with other soundproofing materials, like mass-loaded vinyl or acoustic panels, can lead to even better results in noise reduction. Investing in quality materials is crucial; look for products that have a high Noise Reduction Coefficient (NRC) rating, often above 0.7, to ensure optimal performance.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.