Polyolefin insulation sheets serve a vital role in various industries. These sheets are known for their excellent thermal resistance and lightweight properties. Often made from polymers like polyethylene, they are versatile and durable solutions for insulation needs.

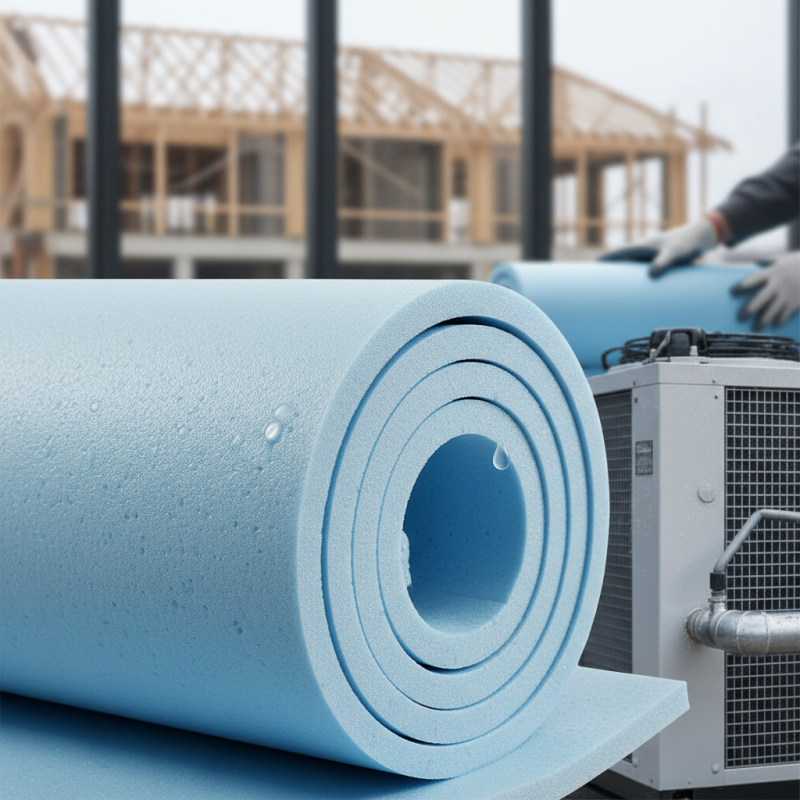

In construction and manufacturing, polyolefin insulation sheets are widely utilized. They protect against heat loss and moisture intrusion. This helps improve energy efficiency in buildings. Moreover, their chemical resistance makes them suitable for industrial applications, such as refrigeration systems. However, one must consider their limitations under extreme conditions.

Despite their benefits, polyolefin insulation sheets may not be the best choice for every situation. Users often overlook necessary installation precautions. Understanding the environment and specific applications can lead to better results. A careful evaluation can maximize performance and ensure safety in various settings.

Polyolefin insulation sheets are crucial in various applications. These sheets are made from polymers like polyethylene and polypropylene. This composition gives them outstanding thermal and electrical insulation properties. They are lightweight but durable. Their flexibility allows for easy application in complex environments.

These sheets are used in construction and electronics. In buildings, they provide excellent thermal insulation. They help to minimize energy costs by reducing heat loss. In electronics, polyolefin sheets protect sensitive components from moisture and thermal damage. Their chemical resistance enhances their suitability for many industrial applications.

Despite their advantages, there are some challenges. For example, their performance can decline under extreme temperatures. Proper installation is crucial to maximizing their benefits. Care should be taken to choose the right type for specific needs. Overall, polyolefin insulation sheets are valuable in many industries, yet users must understand their limitations.

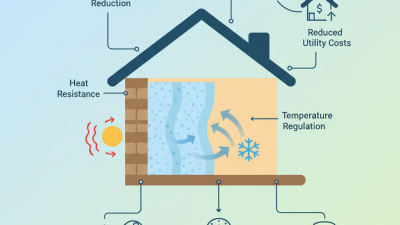

Polyolefin insulation sheets have gained popularity in various industries due to their unique properties. These sheets are lightweight and flexible, making them easy to handle and install. The thermal resistance of polyolefin sheets can reach R-values of up to 3.0, according to industry standards. This efficiency helps reduce energy costs in buildings.

One of the significant advantages is their resistance to moisture and chemicals. Studies show that polyolefin sheets can withstand exposure to various substances, making them ideal for agricultural and industrial applications. Additionally, they are durable, with a lifespan that can exceed 20 years in various conditions. However, some common issues arise, such as difficulties in ensuring proper adhesive bonding. Proper installation is critical to maximizing their performance.

Moreover, polyolefin sheets are often considered environmentally friendly. Many are produced using recycled materials, aligning with sustainability goals. However, the recycling process sometimes lacks efficiency, leading to debates about their overall environmental impact. It's essential for users to weigh the benefits against these challenges when incorporating polyolefin insulation sheets into their projects.

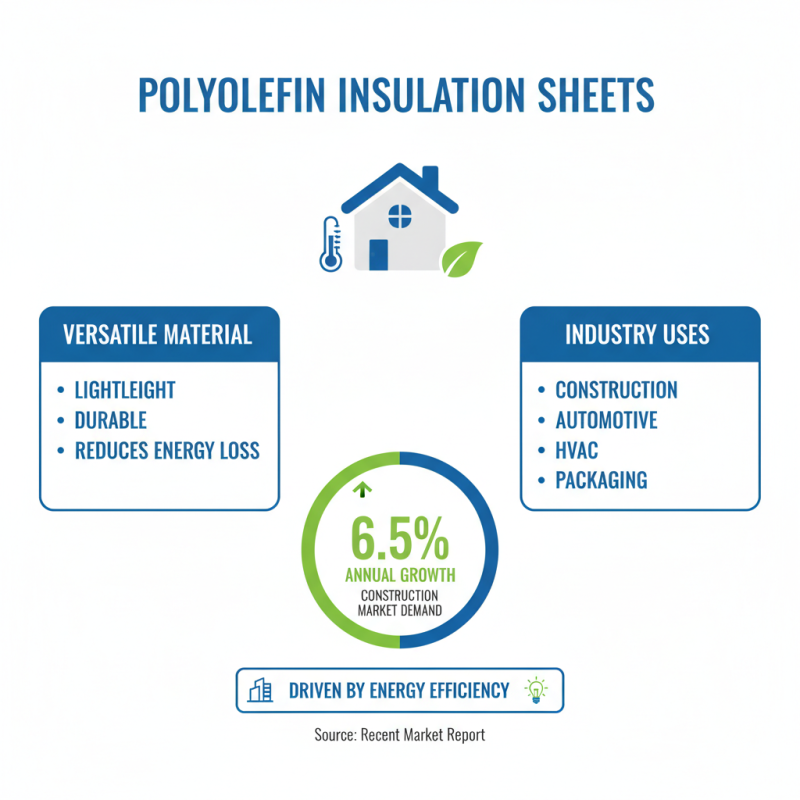

Polyolefin insulation sheets are versatile materials used in various industries. Their lightweight and durable properties make them ideal for reducing energy loss. According to a recent market report, the demand for polyolefin insulation in construction is expected to grow by 6.5% annually. This growth is driven by the need for energy efficiency in commercial and residential buildings.

In the automotive industry, polyolefin materials are used to reduce vehicle weight. This helps improve fuel efficiency and lower emissions. A study shows that using lightweight materials can enhance performance by 10%. However, many manufacturers still face challenges in balancing cost and performance. Some companies struggle to adopt these advanced materials due to high initial investment costs.

The electrical sector also benefits from polyolefin insulation sheets. They are used to protect wires and cables, ensuring safety and reliability. A report highlights that around 20% of electrical failures are linked to insulation issues. Despite the advantages, inconsistencies in quality control can lead to product failures. Ensuring uniformity remains essential for manufacturers to meet industry standards.

Polyolefin insulation sheets provide excellent thermal resistance and versatility for various applications. When installing these sheets, precision is key. Start by measuring the area accurately. Ensure the surface is clean and dry before you begin. Applying the sheets in extreme weather might affect their adhesion. Plan your installation days.

Tips: Use a utility knife for precise cutting. The edges must be smooth to avoid heat loss.

Ensure proper alignment during installation. Overlaps should be at least 3 inches to provide optimal insulation. Consider using a heat gun for better adhesion in colder temperatures. Regular checks during the installation process help identify mistakes early on.

Tips: Check the manufacturer's guidelines for specific installation techniques. Do not rush the process; take your time to achieve a good finish. Occasionally, practice is needed to perfect the technique.

This chart illustrates the effectiveness of polyolefin insulation sheets across various applications including thermal insulation, electrical insulation, moisture barriers, chemical resistance, and lightweight construction. Each application is rated on a scale of 1 to 100 based on their effectiveness.

When considering insulation materials, polyolefin sheets stand out due to their versatility and durability. These sheets are made from polyethylene or polypropylene, offering excellent thermal resistance. They excel in both moisture resistance and insulation performance, making them popular in various industries.

Polyolefin insulation compares favorably with alternatives like fiberglass or foam. While fiberglass can irritate skin and foam may degrade over time, polyolefin is often much easier to handle. Its lightweight nature means lower transportation costs. However, some might find it less effective in extreme temperatures.

Tips: Always assess your specific needs. Think about where the insulation will be used. Installation can be tricky despite its lightweight. Make sure to understand how to properly fit or cut the sheets.

Furthermore, ensure that you consider environmental impact. Polyolefin is recyclable, but its production process isn't perfect. Some insulation options may have better eco-friendly credentials. Reflecting on these factors can help you make a better choice.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.