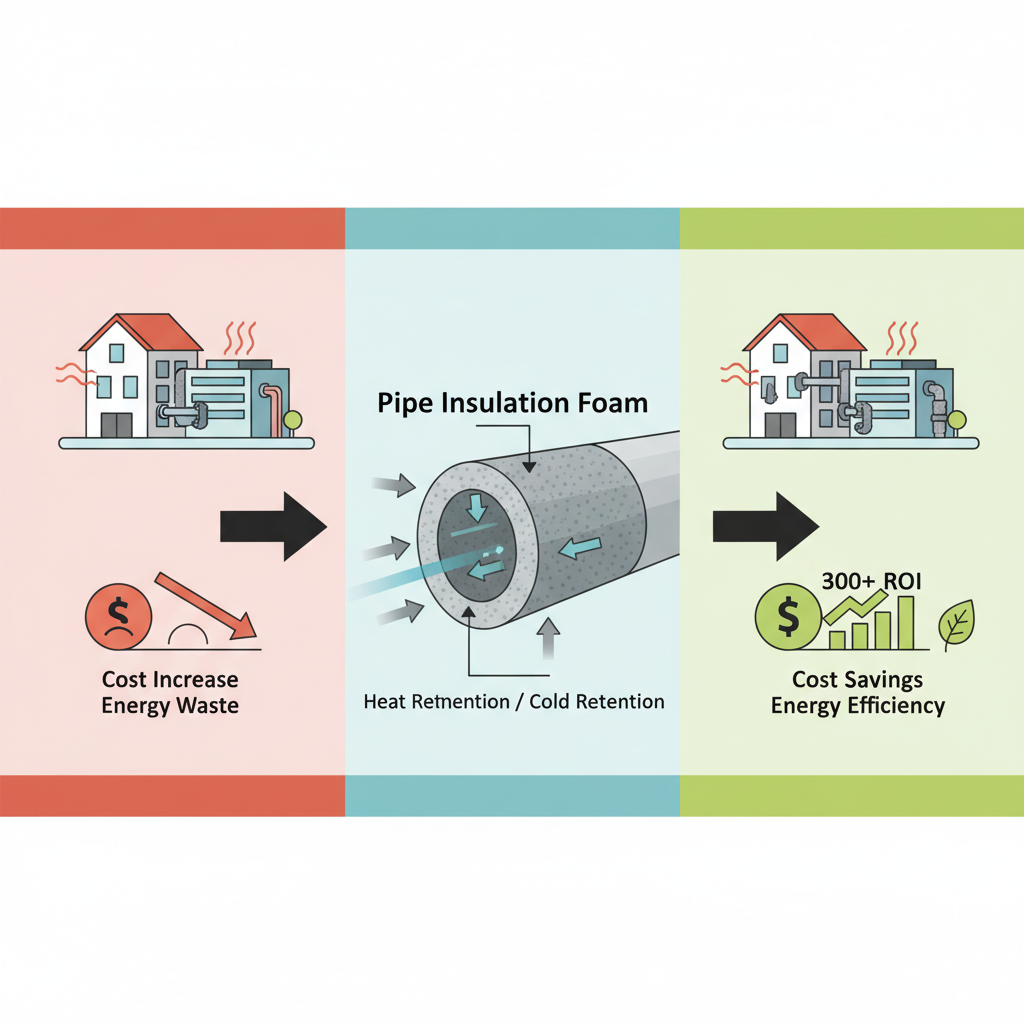

In the quest for energy efficiency and cost savings, the significance of effective thermal management cannot be overstated. Pipe insulation foam has emerged as a critical component in reducing energy losses in heating, cooling, and plumbing systems. According to a report by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE), poorly insulated pipes can lead to energy losses of up to 30%, translating into substantial financial burdens for both residential and commercial properties. Experts emphasize that investing in quality insulation materials is paramount in mitigating these losses.

Dr. Emily Thornton, a leading authority on building energy efficiency, underscores the importance of pipe insulation foam in optimizing energy usage. She states, "Properly installed pipe insulation not only enhances system performance but can also yield significant long-term cost savings for property owners." This perspective aligns with industry insights, which suggest that utilizing pipe insulation foam can lead to a return on investment (ROI) of over 300% within just a few years due to reduced energy costs. By prioritizing pipe insulation foam, homeowners and businesses can create a more efficient, sustainable environment while simultaneously easing their financial burdens.

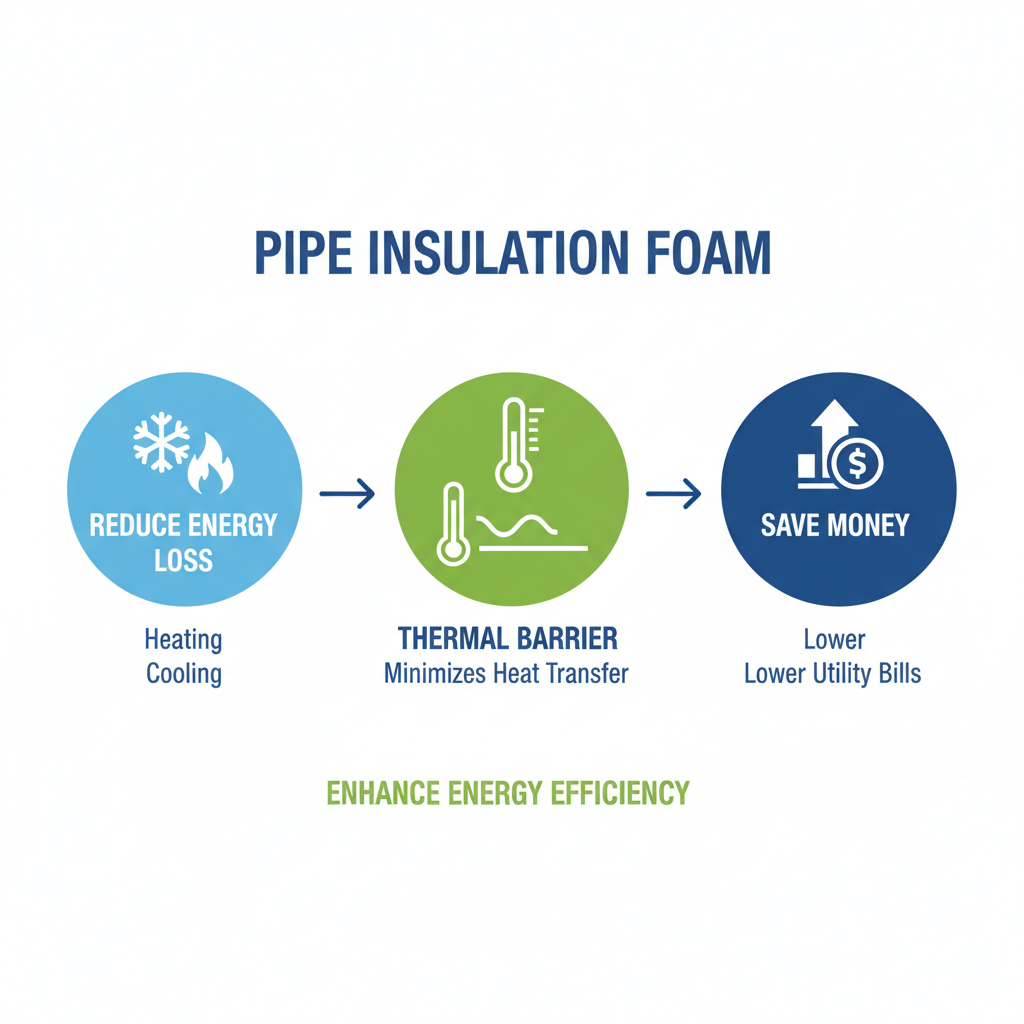

Pipe insulation foam plays a crucial role in enhancing energy efficiency and achieving cost savings for both residential and industrial applications. This type of insulation helps minimize heat loss in pipes, which can significantly reduce energy consumption, particularly in heating systems. By maintaining the desired temperature of fluids traveling through pipes, energy is conserved, leading to lower utility bills. The effective thermal resistance provided by materials such as polyurethane foam or elastomeric foam ensures that buildings can operate efficiently regardless of external temperature fluctuations.

Moreover, the adoption of pipe insulation foam has additional environmental benefits. As energy efficiency improves, the overall carbon footprint of buildings decreases, contributing to sustainability goals. Furthermore, with increasing awareness of energy-saving technologies, the market for pipe insulation foam is expected to grow substantially. This growth presents opportunities for both manufacturers and contractors to innovate and expand services, ensuring that clients can access the most effective insulation solutions available today. By choosing high-quality pipe insulation foam, consumers can invest in long-term savings while simultaneously supporting a greener future.

Pipe insulation foam plays a crucial role in reducing energy loss within heating and cooling systems. By creating a thermal barrier around pipes, this type of insulation minimizes heat transfer, preventing valuable energy from escaping in winter and reducing heat absorption in summer. As energy costs continue to rise, homeowners and businesses alike are increasingly seeking effective solutions to enhance energy efficiency and reduce their utility bills. Understanding the benefits of pipe insulation foam is essential for those looking to maximize their energy savings.

**Tips for Effective Pipe Insulation:**

1. Ensure proper installation: Use high-quality adhesives and follow manufacturer guidelines to secure the insulation firmly around the pipes, minimizing gaps that could lead to energy loss.

2. Seal joints and seams: Pay special attention to joints and seams where pipes meet, as these areas are often responsible for significant heat loss. Using additional sealant can help improve overall insulation effectiveness.

3. Regular maintenance: Periodically check the insulation for wear or damage, especially in areas subject to moisture. Keeping insulation intact will help maintain energy efficiency over time.

Investing in pipe insulation foam not only improves the energy efficiency of systems but also contributes to long-term cost savings, making it a beneficial choice for many property owners.

Choosing pipe insulation foam is an increasingly popular strategy for energy efficiency and cost savings in both residential and industrial applications. The longevity of this material translates to significant long-term savings. By minimizing heat loss in plumbing systems, organizations can achieve stable temperatures and reduce the workload on heating and cooling systems, which ultimately leads to lower energy bills. In fact, the growing global demand for eco-friendly construction solutions has propelled the pipe insulation market, projecting notable growth in several regions.

**Tips:** When selecting pipe insulation foam, consider material types like rock wool and elastomeric foam, as they offer different benefits for energy conservation. It's also wise to assess your specific application requirements—be it industrial or residential—to choose the most suitable option. Regular maintenance and timely replacement of aged insulation can further enhance efficiency, ensuring that your investment continues to pay off over time.

This chart illustrates the projected savings over five years from using pipe insulation foam. The consistent increase in savings highlights the long-term financial benefits associated with enhanced energy efficiency.

When considering the installation process for

pipe insulation foam, it is crucial to follow specific best practices to maximize its effectiveness. According to the U.S. Department of Energy, proper insulation can save homeowners between

10% to

20% on their energy bills each year. To achieve these savings, the first step is to ensure that the pipes are clean and dry before application. This helps create a secure bond between the foam and the surface of the pipes, leading to better thermal resistance.

During installation, it is recommended to select the appropriate pipe insulation foam type based on the temperature requirements. For instance,

closed-cell foam is ideal for cold-water pipes, while

open-cell foam is suitable for hot-water pipes. The application should cover all exposed areas, ensuring that all joints and seams are sealed to prevent thermal bridging. Industry reports suggest that neglecting to insulate just a small section of your piping can significantly reduce overall energy efficiency, making

installation technique vital for achieving the best performance and cost savings in energy bills.

When evaluating pipe insulation options for energy efficiency and cost savings,

pipe insulation foam emerges as a commendable choice against traditional materials like

rock wool and glass wool.

Foam insulations, such as polyurethane and elastomeric foam, are recognized for their superior thermal performance.

This means they effectively minimize heat loss, leading to lower energy bills and enhanced comfort.

In contrast, materials like phenolic foam also offer good insulation but can be more expensive and less readily available.

Additionally, the market is witnessing the rise of innovative insulating materials, including 3D printed thermal insulators, which align with sustainable practices by reducing waste and utilizing advanced manufacturing techniques. These emerging materials could potentially rival conventional pipe insulation foams and provide unique benefits in terms of customization and installation efficiency. As the demand for energy-efficient solutions continues, the comparison between pipe insulation foam and these alternatives reveals key insights about their respective advantages, solidifying the former's position as a vital component in modern insulation strategies.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.