In today's fast-paced world, the significance of a well-designed workspace cannot be overstated, as it directly impacts employee comfort and productivity. A growing body of research underscores the role of sound environment in workplace performance, with studies revealing that excessive noise can diminish concentration and lead to increased stress levels. According to a report by the World Health Organization, a noise level exceeding 55 decibels can disrupt cognitive function, causing a productivity dip of approximately 20%. To combat these challenges, many businesses are turning to innovative solutions such as noise insulation foam. This specialized material not only reduces ambient noise but also enhances overall acoustic comfort, creating an environment conducive to focus and creativity. By investing in noise insulation foam, organizations can significantly improve the workplace atmosphere, leading to higher employee satisfaction and, ultimately, better business outcomes.

Noise insulation foam is a crucial element in optimizing office and living spaces, offering significant benefits in reducing sound pollution and enhancing overall well-being. According to a report by the Acoustical Society of America, excessive noise can lead to reduced productivity, increased stress levels, and decreased cognitive performance. By implementing noise insulation foam, spaces can achieve a reduction in sound transmission by up to 90%, fostering an environment conducive to concentration and relaxation.

There are various types of noise insulation foams available, each designed for specific applications. Open-cell foam is commonly used in wall cavities and ceilings, known for its excellent sound absorption qualities. In contrast, closed-cell foam offers higher density, making it suitable for areas requiring enhanced insulation against both sound and temperature fluctuations. A study conducted by the National Institute of Health highlighted that workplaces utilizing sound-dampening materials reported a 25% improvement in employee productivity and a significant decrease in absenteeism, demonstrating the profound impact of noise insulation foam on both comfort and efficiency.

| Type of Noise Insulation Foam | Key Benefits | Ideal Applications | Estimated Cost per Square Foot |

|---|---|---|---|

| Acoustic Foam | Reduces echo and sound reflection | Recording studios, home theaters | $1.50 |

| Mass Loaded Vinyl | Blocks sound transmission | Walls, ceilings, floors | $2.00 |

| Polyester Acoustic Panels | Absorbs sound and improves acoustics | Offices, classrooms | $1.00 |

| Foam Padding | Provides comfort and sound dampening | Furniture, commercial spaces | $0.75 |

| Soundproofing Curtains | Reduces outside noise and enhances privacy | Windows, doors | $1.25 |

When selecting the right noise insulation foam for your space, it's essential to consider the specific needs of your environment. Different types of foam vary in density and composition, impacting their ability to absorb sound. For instance, open-cell foam is generally more effective in reducing mid to high-frequency sounds, making it suitable for home offices or studios where conversation and electronic noise may be present. Conversely, closed-cell foam can provide better insulation against low-frequency noises, such as those from heavy machinery or traffic.

In addition to the type of foam, thickness and installation method also play crucial roles. Thicker foam panels can provide more significant soundproofing benefits, while strategically placing them in areas where sound waves bounce can enhance overall effectiveness. Consider using acoustic wall panels or ceiling tiles for a more polished look and improved aesthetics. Ultimately, evaluating both the technical specifications and practical applications of different noise insulation foams will ensure that you create a comfortable, productive space tailored to your needs.

Noise insulation foam is a crucial element in transforming your living or working space into a haven of comfort and productivity. According to a report from the Acoustical Society of America, even minor ambient noise can reduce workplace productivity by as much as 66%. To combat this, installing noise insulation foam effectively reduces unwanted sound, facilitating better concentration and a more pleasant environment.

When installing noise insulation foam, proper techniques can significantly enhance its effectiveness. First, always ensure that the surfaces where the foam will be applied are clean and dry. Second, consider the layout—place the foam strategically in areas where noise is most likely to enter, such as walls shared with noisy neighbors or the ceiling if you are on a lower floor. Lastly, employing an adhesive specifically designed for acoustic foam will ensure a strong bond and a seamless installation, maximizing soundproofing capabilities.

Another essential tip is to use a combination of different foam products. For instance, pairing wedge-shaped foam panels with bass traps can address a broader range of sound frequencies, leading to optimal noise reduction. The National Institute of Health states that well-insulated environments are linked to reduced stress levels, ultimately contributing to a healthier and more productive lifestyle.

Incorporating design aesthetics with noise insulation solutions is not just about functionality; it’s about creating an environment that breeds comfort and productivity. According to a report by the World Health Organization, excessive noise can lead to increased stress levels and reduced performance in workspaces. Noise insulation foam offers an effective solution by minimizing disruptive sounds while allowing for creative design implementations. By integrating colors, patterns, and textures that align with an organization’s brand identity, these acoustic solutions can enhance the visual appeal of a space while catering to its auditory needs.

Recent studies indicate that well-designed acoustic treatments can improve workplace productivity by up to 20%. This is particularly relevant in open office layouts, where noise can be a significant distraction. Designers are now leveraging noise insulation materials not only for their acoustic benefits but also to create visually engaging environments that people want to spend time in. Brands like Snowsound and FoamTouch have developed innovative foam products that combine aesthetics with superior sound absorption, demonstrating that functional solutions can also be beautifully designed. By prioritizing both form and function, businesses can foster spaces where comfort and productivity go hand in hand.

This chart illustrates the various benefits of using noise insulation foam in spaces, focusing on comfort and productivity. The data represents the percentage improvement based on user feedback.

Noise in the workplace can significantly hinder productivity, and research consistently supports this assertion. According to a study conducted by the World Health Organization (WHO), excessive noise can lead to decreased concentration, increased stress levels, and lower overall job satisfaction. In fact, the findings revealed that employees in noisy environments could lose up to 60 minutes of productive work time each day, translating to substantial economic losses for businesses.

Implementing noise insulation foam is a practical solution that can transform workspaces into productive havens. A report from the National Institute for Occupational Safety and Health (NIOSH) indicates that companies that prioritize sound management saw a 35% increase in employee performance and engagement. By reducing ambient noise levels, insulation foam not only enhances speech privacy but also creates a more comfortable environment, fostering better communication and collaboration among team members. As businesses continue to strive for improved productivity, investing in effective noise insulation strategies becomes increasingly critical.

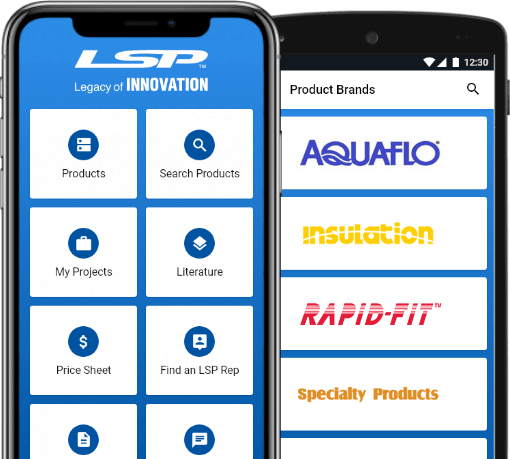

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.