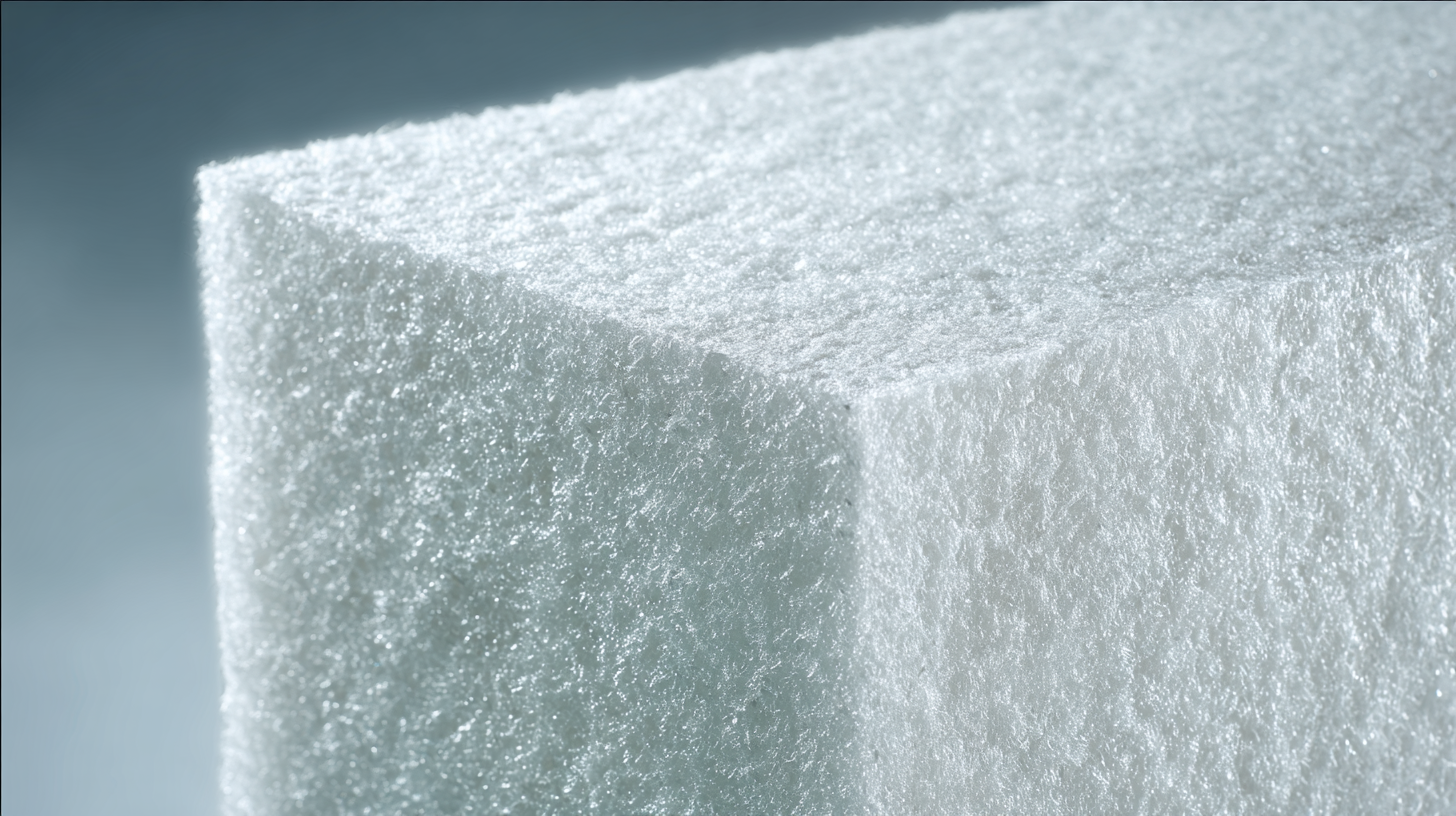

In an era where sustainability is paramount, maximizing energy efficiency in buildings has become increasingly essential. One of the most effective solutions is the use of insulation polystyrene, a versatile material known for its superior thermal performance and environmental benefits. By incorporating insulation polystyrene into building designs, homeowners and architects alike can create energy-efficient spaces that reduce heating and cooling costs while minimizing the ecological footprint.

This guide will explore practical strategies to effectively utilize insulation polystyrene in construction, showcasing its applications and advantages in achieving sustainable building solutions. As we delve into the various aspects of insulation polystyrene, we will highlight best practices that not only enhance energy efficiency but also contribute to a greener future.

Polystyrene insulation is at the forefront of sustainable building solutions, playing a crucial role in maximizing energy efficiency. According to the U.S. Department of Energy, properly insulated buildings can reduce heating and cooling costs by 30% or more. Polystyrene, both expanded (EPS) and extruded (XPS), offers high thermal resistance with R-values ranging from 4 to 6 per inch, making it a top choice for energy-efficient construction. This exceptional insulation capability helps minimize energy loss, contributes to lower utility bills, and enhances overall indoor comfort.

Moreover, polystyrene insulation is not only effective but also environmentally friendly. A study by the American Chemical Society highlights that using polystyrene can lead to significant reductions in greenhouse gas emissions by decreasing the energy required for heating and cooling. Its lightweight nature and ease of installation further streamline the construction process, reducing labor costs and material waste. As the architecture and construction industries continue to focus on sustainable practices, polystyrene insulation stands out as a reliable solution for achieving energy efficiency while supporting eco-friendly building initiatives.

When selecting polystyrene insulation for sustainable building projects, it's essential to consider several critical factors to maximize energy efficiency. First, look at the insulation's R-value, which measures thermal resistance. According to the U.S. Department of Energy, polystyrene insulation can achieve an R-value of up to 5 per inch, making it a highly effective option for minimizing heat transfer. This characteristic is vital in maintaining consistent indoor temperatures, reducing the need for heating and cooling, which accounts for approximately 50% of energy usage in residential buildings.

Another important factor is durability and moisture resistance. A study by the Oak Ridge National Laboratory highlights that extruded polystyrene (XPS) not only provides excellent thermal performance but also offers superior moisture resistance, preventing mold and decay that can compromise energy efficiency. Additionally, consider the environmental impact by choosing polystyrene products with recycled content, as reported by the National Association of Home Builders, which indicates that the demand for sustainable materials is significantly rising in the construction industry.

Integrating these insights can lead to choosing the right polystyrene insulation, ultimately contributing to greener and more energy-efficient buildings.

Proper installation of polystyrene insulation is critical to achieving maximum energy efficiency in sustainable building practices. The first step in the installation process involves selecting the right type of polystyrene—expanded polystyrene (EPS) or extruded polystyrene (XPS)—based on the specific needs of the project. Once selected, careful measurement and cutting of the boards to fit snugly into walls, roofs, and floors are essential. This ensures that there are minimal gaps, which can compromise thermal performance.

Additionally, pay close attention to the seams between boards. Utilizing a high-quality insulation tape or sealant to seal these gaps will significantly enhance the insulating properties, preventing air leaks that can lead to energy loss. It’s important to consider the installation environment; for instance, working in consistent temperatures and ensuring the surface is clean and dry will facilitate better adhesion and improve overall effectiveness. By following these steps diligently, builders can maximize the performance of polystyrene insulation and contribute to more energy-efficient, sustainable structures.

The adoption of insulation polystyrene, particularly expanded polystyrene (EPS) and extruded polystyrene (XPS), has proven pivotal in enhancing energy efficiency within building solutions. According to the U.S. Department of Energy, buildings account for approximately 40% of total energy consumption and nearly 70% of electricity use in the United States. By incorporating polystyrene insulation, energy savings can reach up to 30% annually through effective thermal resistance. This translates not only into reduced energy bills for consumers but also contributes significantly to lower greenhouse gas emissions.

Moreover, a study by the Environmental Protection Agency highlights that improved insulation can lead to an annual reduction of up to 5 million tons of CO2 emissions per year nationwide, thereby underscoring polystyrene’s role in sustainable building practices. The versatility of polystyrene in various applications, from wall cavities to roof installations, enhances overall building thermal performance. As buildings strive to meet energy efficiency standards, the integration of insulation polystyrene presents a remarkably effective solution that not only supports environmental objectives but also aligns with economic feasibility by lowering operational costs over time.

Polystyrene insulation plays a crucial role in sustainable building solutions, particularly when considering its recyclability and environmental impact. As a highly effective insulating material, polystyrene minimizes energy loss, which directly contributes to reducing overall energy consumption in buildings. This energy efficiency is critical in the context of global sustainability goals, as it lowers greenhouse gas emissions and lessens the reliance on fossil fuels.

Moreover, polystyrene's recyclability significantly enhances its sustainability profile. Many products made from polystyrene, such as foam packaging and insulation boards, can be recycled, diverting waste from landfills. Recycled polystyrene can be reprocessed into new products, thus promoting a circular economy. However, challenges remain regarding the collection and processing of polystyrene waste, which necessitates improved recycling infrastructures and public awareness to maximize its environmental benefits. Balancing the advantages of energy efficiency with responsible disposal practices is essential for leveraging polystyrene as a sustainable building material.

| Dimension | Value | Notes |

|---|---|---|

| Thermal Conductivity (λ) | 0.030 W/m·K | Low thermal conductivity contributes to energy efficiency |

| Recyclability Rate | 100% | Fully recyclable, reducing landfill impact |

| SGS Certificate | Yes | Meets international safety and environmental standards |

| CO2 Emissions during Production | 450 kg/m³ | Efforts to minimize carbon footprint |

| Lifespan | 50 years | Durability reduces replacement frequency |

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.