Choosing the right insulation is essential for a successful project. One effective option is thermobreak polyolefin insulation. This material offers unique benefits that make it ideal for various applications.

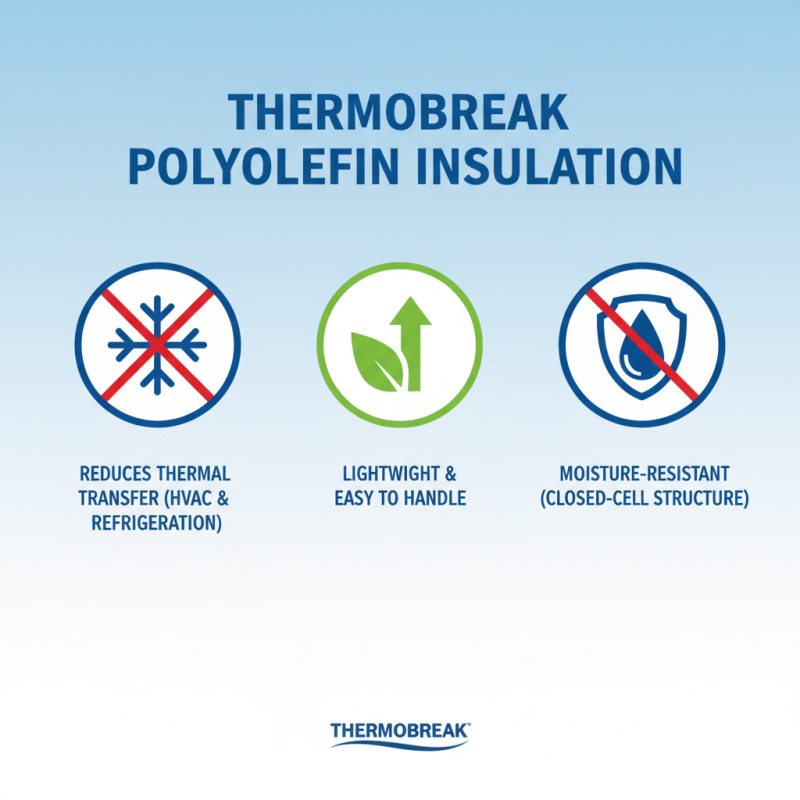

When selecting thermobreak polyolefin insulation, consider its thermal performance. It provides excellent resistance to heat flow. This means that buildings can maintain temperature effectively. Also, think about its moisture resistance. This feature helps prevent mold growth, protecting the integrity of structures.

However, not all projects may benefit equally from this insulation. It’s important to evaluate the specific needs of your project. Conduct thorough research and weigh the advantages of thermobreak polyolefin insulation against alternatives. Sometimes, the best choice may not be the most obvious one.

Thermobreak polyolefin insulation is designed to reduce thermal transfer. It serves various applications such as HVAC systems and refrigeration. This insulation material is lightweight, making it easy to handle. Its closed-cell structure prevents moisture absorption, which is crucial for thermal efficiency.

When considering its applications, think about where heat loss or gain can occur. For example, in a commercial building, pipes carrying hot water need proper insulation. Inadequate insulation can lead to condensation issues and costly energy losses. Many users overlook these details, which might result in poor performance.

Thermobreak insulation is also resistant to chemicals. This quality makes it suitable for industrial environments. However, not every project will benefit from this type of insulation. Evaluating specific project needs is essential. Are there possible allergens or other sensitivities? Reflecting on these factors can guide you to better decisions.

When choosing thermobreak polyolefin insulation, evaluating key properties is crucial. These materials offer excellent thermal resistance, a primary concern for energy efficiency. According to industry reports, thermobreak insulation can achieve a thermal conductivity value as low as 0.020 W/m·K. This low value means less energy loss, translating into significant savings on heating and cooling costs.

Moreover, moisture resistance is another important property. Thermobreak polyolefin insulation has a closed cell structure, making it impervious to water. This helps prevent mold growth. A report from the Insulation Contractors Association indicates that up to 40% of energy inefficiency stems from moisture problems. Thus, selecting materials that resist water intrusion can be defining for long-term performance.

Consider the material’s fire resistance as well. While many insulations meet minimum fire standards, thermobreak offers superior performance in critical applications. However, installation does matter. Poor application can lead to gaps, undermining the insulation’s effectiveness. It's essential to reflect on these factors when planning your project. What may seem like small details can lead to larger issues down the line. Always prioritize these key properties for a successful insulation solution.

| Property | Description | Value | Importance |

|---|---|---|---|

| Thermal Conductivity | Measure of insulation's ability to conduct heat | 0.022 W/m·K | High importance for energy efficiency |

| Density | Weight per unit volume of insulation material | 35 kg/m³ | Moderate importance for structural considerations |

| Moisture Resistance | Ability to withstand water absorption | < 0.01% absorption | Critical for preventing mold and degradation |

| Fire Performance | Reaction to fire according to safety standards | Class E (Euroclass) | Essential for safety compliance |

| Thermal Stability | Performance under varying temperature conditions | -40°C to 100°C | High importance for versatile applications |

Choosing the right insulation for your project can be daunting. Start by identifying specific project requirements. Consider the climate in your area. For example, will you need insulation that withstands cold or heat? Each requirement will affect your choice.

Next, assess the space where the insulation will be installed. Is it a small, enclosed area or a vast, open space? The size and structure influence thermal performance. You might need a thicker insulation layer for larger areas. Don’t overlook moisture levels, either. Humidity can significantly impact insulation effectiveness.

Finally, budget constraints can shape your decision. Higher quality usually means higher costs. Reflect on the long-term benefits. Sometimes, spending more initially leads to greater savings over time. Balancing cost and performance is crucial, even if it feels frustrating. Each project is unique, so take time to evaluate these factors carefully.

When comparing Thermobreak polyolefin insulation to other options, it's essential to consider key features. Thermobreak offers highly effective thermal resistance. Its lightweight design makes it easy to handle. Other insulation materials, like fiberglass, can be heavier and more cumbersome.

Look at moisture resistance, too. Thermobreak excels in this area, preventing water absorption. That can lead to mold or degradation in other materials. Traditional options might require more maintenance over time. They can rot or lose effectiveness if not properly installed.

Consider the installation process as well. Thermobreak can be cut and shaped with ease. It adapts quickly to various project needs. Some materials may demand more labor and preparation. This can impact your project timeline and costs. Reflect on these factors carefully as you choose the best insulation for your project.

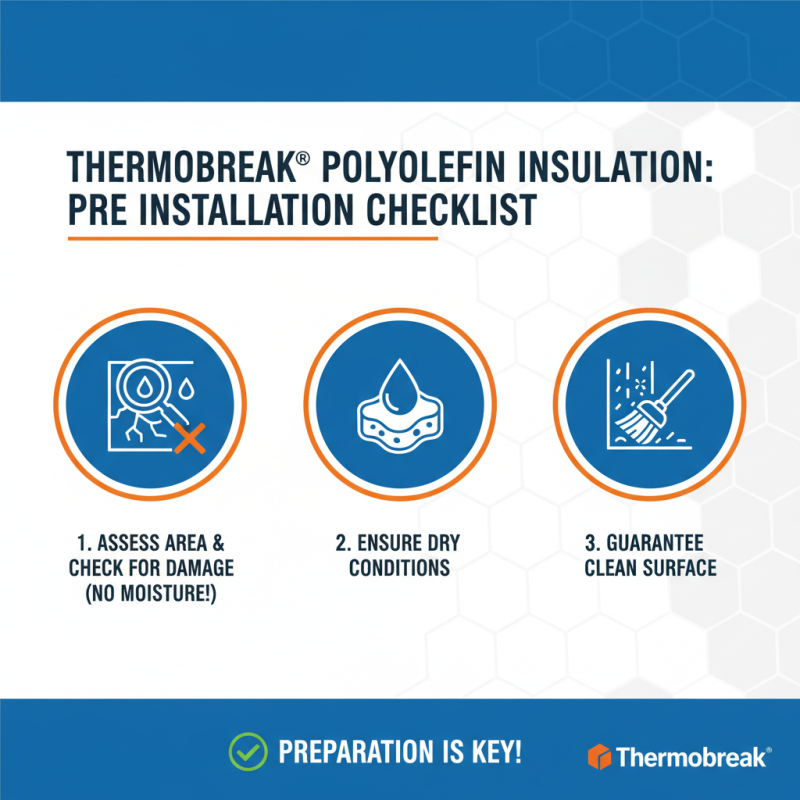

When installing Thermobreak Polyolefin insulation products, preparation is key. Start by assessing the area where the insulation will be applied. Check for any moisture issues or existing damage. Damp conditions weaken the insulation's effectiveness. You want a dry, clean surface before you begin installation.

A critical step is measuring the space accurately. Ensure that every piece fits snugly. If the insulation is too loose, it may lead to air leaks. Check your cuts carefully. Misaligned edges can cause significant energy loss. Always use the right tools for cutting and fitting.

Tips: Don’t rush the installation process. Take time to double-check each fitting. If you encounter issues, pause and analyze the problem. Sometimes, going back to read the instructions can save time and effort. Lastly, consider sealing joints with tape for extra protection against air leakage. Even small gaps can impact energy efficiency.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.