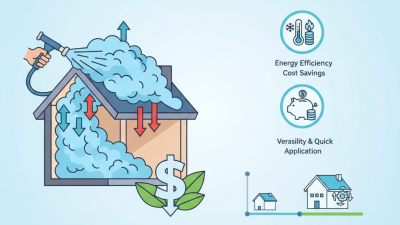

Spray foam insulation has gained popularity among homeowners seeking energy efficiency. Expert Eric Johnson, a leading figure in the insulation industry, states, “Proper insulation can save you money and improve comfort.” This simple yet profound idea guides many in choosing the right materials for their homes.

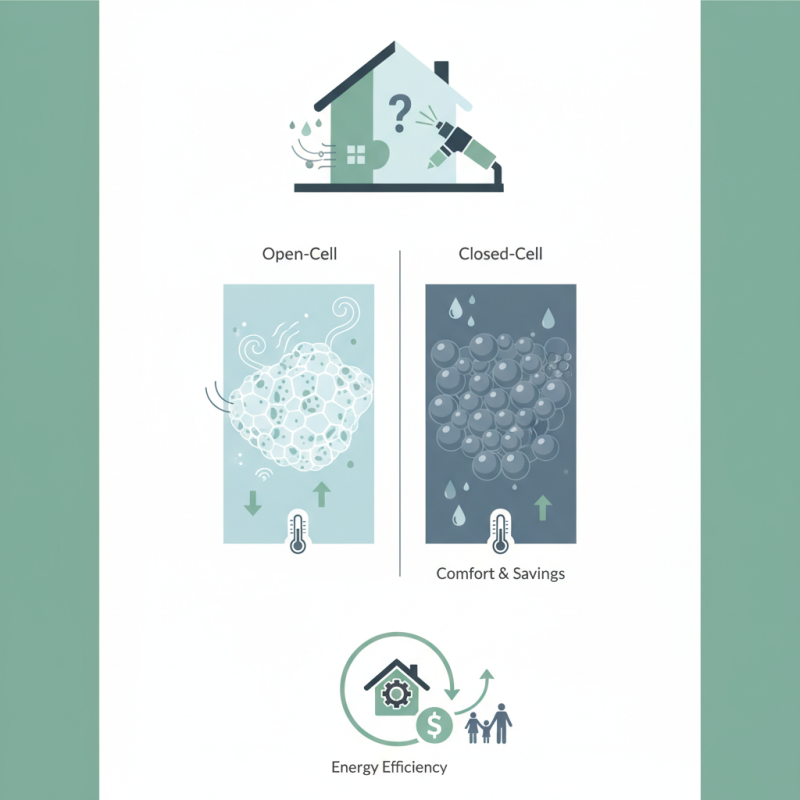

When selecting spray foam insulation, consider the types available. Open-cell and closed-cell foams serve different purposes. Open-cell foam is lighter and easier to install, while closed-cell foam offers higher R-values and moisture resistance. Each type has its advantages and downsides.

Many homeowners overlook these details, leading to regrets down the line. Proper research is crucial. Understanding your specific needs can drastically change your results. The ideal insulation choice integrates well with your home’s structure, providing lasting benefits.

Spray foam insulation is an excellent choice for many homeowners. It offers superior energy efficiency. Understanding its basics will help you make an informed decision. Spray foam comes in open-cell and closed-cell types. Each has distinct properties and applications.

Open-cell foam is lighter and less dense. It works well for interior areas, like walls and ceilings. Closed-cell foam provides a higher R-value. This makes it suitable for exterior walls and roofing. Consider your insulation goals when choosing between them. Know the climate in your area too.

The installation process can be tricky. Misapplication can lead to issues. Ensure you hire qualified professionals for the job. Check reviews and ask for references. Their expertise can save you from costly mistakes. Remember, insulation is not just about material; it’s also about how well it's applied. A poorly installed foam can compromise its effectiveness.

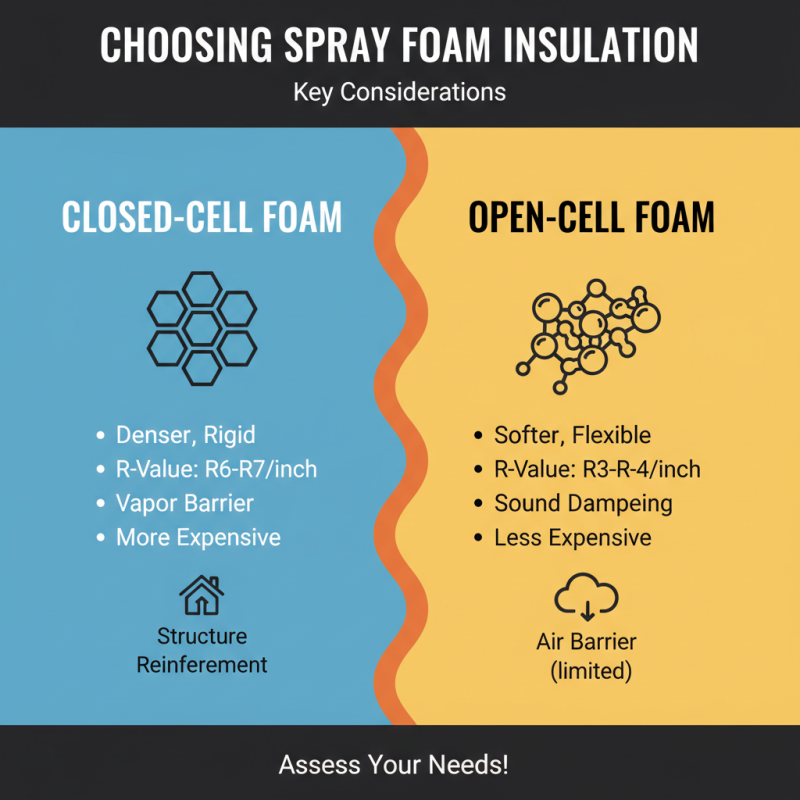

When considering spray foam insulation for your home, understanding the differences between open-cell and closed-cell foam is crucial.

Open-cell foam has a lower density. It expands more, filling gaps and cracks effectively. Typically, it provides an R-value of about 3.5 per inch. This type is ideal for interior applications, like walls and attics. Its porous structure allows for sound absorption, which is great for noise reduction.

Closed-cell foam, on the other hand, is denser and provides a higher R-value, up to 7 per inch. This insulation type is more moisture-resistant, making it suitable for exterior applications. However, it comes at a higher cost. According to industry reports, while open-cell foam might average around $0.35 per board foot, closed-cell foam can reach $1.00 per board foot or more. This price difference can impact your budget significantly, leading to reflections on which type genuinely meets your needs.

Both foam types have limitations. Open-cell foam may not perform well in areas prone to high humidity or moisture accumulation. Closed-cell foam, despite its superior properties, can lead to over-insulation in some cases, which might trap moisture within walls. Understanding your home's specific insulation needs is essential, yet some homeowners may overlook this detail, leading to potential long-term issues. Balancing cost, performance, and suitability is key to making the right choice.

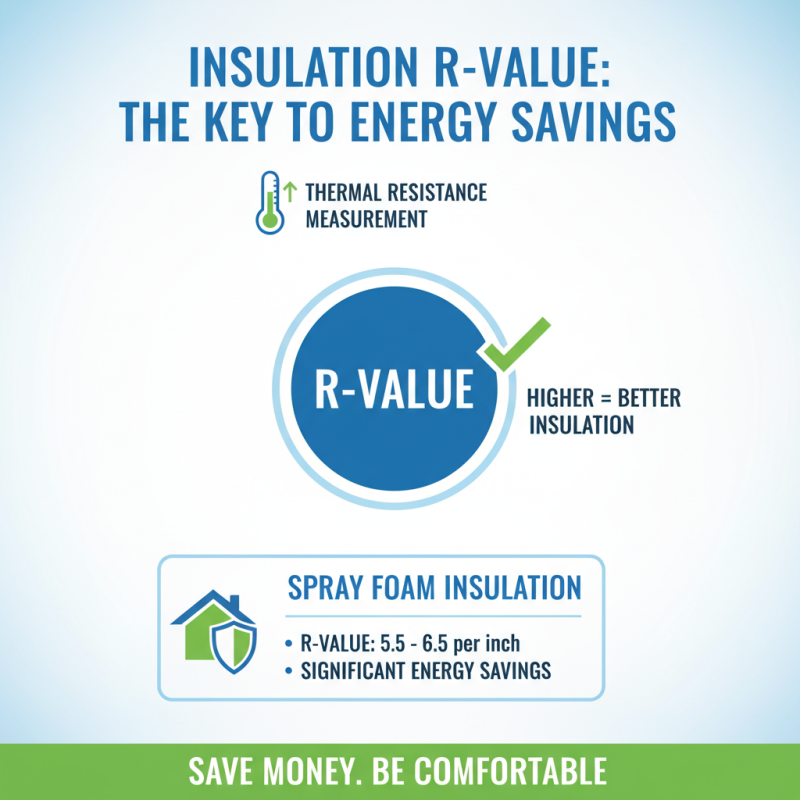

When assessing insulation, R-value is crucial. It measures thermal resistance. A higher R-value indicates better insulation. Generally, spray foam insulation offers impressive R-values, often ranging from R-5.5 to R-6.5 per inch. This shows significant potential for energy savings in homes.

Energy efficiency is closely linked to R-value. According to the Department of Energy, effective insulation can reduce energy costs by 15% to 50%. This creates long-term financial benefits. However, it's vital to consider regional climate when selecting insulation. In colder climates, higher R-values are necessary. In warmer areas, lower values may suffice.

Evaluating your needs also involves understanding potential drawbacks. While spray foam is effective, installation can be challenging. Not all contractors are skilled. Poor application may lead to gaps and reduced efficiency. Homeowners should research and choose qualified professionals. This can make a substantial difference in overall performance.

Choosing the right spray foam insulation for your home requires careful consideration of several factors. The first aspect to think about is the type of foam. Closed-cell spray foam offers better insulation but can be more expensive. Open-cell spray foam, on the other hand, is cheaper and more flexible but may not provide the same sealing properties. Assess your specific needs before deciding.

Another factor is the installation process. Hiring a professional can ensure proper application. However, not everyone can afford this expense. Some homeowners opt for DIY kits, but this can lead to mistakes if not applied correctly. Understand your skill level and comfort with such projects.

Tips: Always check the R-value of the foam. Higher ratings mean better insulation. Consider the climate in your area. It affects the effectiveness of the insulation. Finally, think about potential health concerns. Some foams produce harmful fumes during installation. Research safety measures thoroughly before proceeding.

The installation process of spray foam insulation is crucial for its effectiveness. Begin with a clean surface to ensure proper adhesion. Remove dust, debris, and any old insulation materials. This step can be labor-intensive and often overlooked. Proper preparation sets the stage for a successful application, but many homeowners might miss this step entirely.

Once the area is ready, the spray foam can be applied. It expands upon contact, filling gaps thoroughly. However, it's important to wear protective gear during this process. The chemicals can be hazardous. Some might underestimate the need for safety precautions, which can lead to health issues.

After installation, maintenance is relatively simple. Inspect the foam periodically for damage or wear. It's easy to forget about it until there’s a noticeable issue. Minor repairs can be made with spray foam kits. Regular checks will ensure your insulation remains effective over time. Neglecting these inspections may result in increased energy costs down the line. Maintaining spray foam insulation promotes long-lasting efficiency for your home.

| Aspect | Description |

|---|---|

| Types of Spray Foam | Open-cell foam is less dense and more affordable; closed-cell foam is denser, provides higher insulation value, and is moisture resistant. |

| R-Value | Closed-cell foam has an R-value between 6.5 to 7 per inch, while open-cell foam ranges from 3.5 to 4 per inch. |

| Installation Process | Professional application is recommended; includes surface preparation, spraying the foam, and curing time. |

| Maintenance | Regular inspections for damage, ensure no moisture build-up, and check for integrity of the foam layer. |

| Cost Factors | Depending on area of application, type of foam, and local labor costs; overall installation cost varies widely. |

| Environmental Impact | Look for low global warming potential (GWP) options; foam can contribute to energy efficiency and lower utility bills. |

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.