When embarking on your next construction or renovation project, selecting the right materials is critical to ensure both efficiency and longevity. Among these materials, polyolefin pipe insulation stands out as a highly effective choice for thermal insulation and energy efficiency. This versatile insulation option not only offers excellent thermal resistance but also protects against condensation and energy loss, making it ideal for a variety of applications, from residential to industrial. However, with numerous types and brands available in the market, choosing the most suitable polyolefin pipe insulation can be a daunting task. In this guide, we will explore key factors to consider, such as insulation thickness, pipe diameter compatibility, and fire and moisture resistance ratings. By understanding these aspects, you'll be better equipped to make an informed decision, ensuring that your project benefits from optimal insulation performance and cost-effectiveness.

When embarking on your next construction or renovation project, selecting the right materials is critical to ensure both efficiency and longevity. Among these materials, polyolefin pipe insulation stands out as a highly effective choice for thermal insulation and energy efficiency. This versatile insulation option not only offers excellent thermal resistance but also protects against condensation and energy loss, making it ideal for a variety of applications, from residential to industrial. However, with numerous types and brands available in the market, choosing the most suitable polyolefin pipe insulation can be a daunting task. In this guide, we will explore key factors to consider, such as insulation thickness, pipe diameter compatibility, and fire and moisture resistance ratings. By understanding these aspects, you'll be better equipped to make an informed decision, ensuring that your project benefits from optimal insulation performance and cost-effectiveness.

Polyolefin pipe insulation has emerged as a vital component in modern construction and industrial applications, thanks to its impressive thermal properties and versatility. According to a recent report by the International Energy Agency, effective insulation can reduce energy consumption in heating and cooling systems by up to 30%, making polyolefin materials an excellent choice for energy-efficient projects. With a low thermal conductivity ranging from 0.020 to 0.040 W/m·K, polyolefin insulation helps maintain desired temperatures in pipes, thereby enhancing overall system efficiency.

Moreover, polyolefin insulation is well-suited for various applications, including residential plumbing, commercial HVAC systems, and industrial processes. The material is resistant to moisture, which prevents condensation and mold growth—a critical factor in maintaining air quality and structural integrity. According to research from the North American Insulation Manufacturers Association, nearly 70% of commercial building owners reported significant savings in energy costs after switching to polyolefin insulation. Its lightweight nature and ease of installation further contribute to its growing popularity in new construction and retrofit projects alike, demonstrating its effectiveness in addressing both performance and sustainability needs in today's market.

When selecting polyolefin pipe insulation for your next project, evaluating thermal performance metrics is crucial. Polyolefin insulation materials, known for their lightweight and durable properties, should ideally have a low thermal conductivity value. According to recent industry reports, polyolefin materials typically exhibit thermal conductivity values ranging from 0.21 to 0.25 W/m·K, making them effective at minimizing heat transfer. This quality not only enhances energy efficiency but also contributes to maintaining optimal temperature levels within piping systems.

Tips for selecting the right insulation include reviewing the insulation thickness required for your specific application. Insulation thickness plays a significant role in overall thermal performance; increasing the thickness can significantly reduce heat loss. Additionally, consider the insulation's temperature rating. Polyolefin insulation is effective for a variety of temperature ranges, but ensuring compatibility with your project's specific conditions is essential for maximizing efficiency.

Furthermore, always check the insulation's moisture resistance and fire safety ratings. Enhanced moisture resistance is particularly beneficial in humid environments, while adhering to fire safety standards is critical for compliance and safety. By prioritizing these thermal performance metrics, you can effectively choose the best polyolefin pipe insulation for your project.

When assessing the cost-effectiveness of polyolefin pipe insulation against alternative materials, it is crucial to consider both the economic and environmental implications.

Polyolefin insulation is derived from petroleum-based resources, yet it offers significant advantages in terms of thermal efficiency and resistance to moisture. This can lead to decreased energy costs over time, as well as improved system performance. Additionally, when compared to traditional insulation materials, polyolefin often shows a lower installed cost due to its lightweight properties and ease of handling.

On the other hand, environmentally friendly materials are gaining traction as alternatives to polyolefin. Sustainable bioplastics and natural fiber composites, for example, are emerging as viable options for various applications, including insulation. These materials often feature a reduced carbon footprint and are derived from renewable resources, highlighting their potential for a more sustainable approach in building projects. By conducting a life-cycle assessment of these alternatives, project managers can better understand their long-term benefits and potential cost savings, allowing for more informed decisions when selecting insulation materials.

When selecting polyolefin pipe insulation for your next project, it is crucial to consider the various industry standards and certifications that dictate performance and safety. According to the American Society for Testing and Materials (ASTM), polyolefin insulation must meet specific thermal resistance and fire safety criteria to be suitable for commercial applications. Insulation products are often rated for their R-value, and polyolefin materials generally exhibit R-values ranging from 3.5 to 4.5 per inch of thickness, indicating their effectiveness in reducing heat transfer.

Moreover, industry certifications such as the Underwriters Laboratories (UL) listing and the National Sanitation Foundation (NSF) approval ensure that the insulation complies with stringent safety and health standards. A 2020 report by the Insulation Contractors Association of America highlights that using certified polyolefin pipe insulation can improve energy efficiency by up to 20%, directly contributing to reduced operational costs. Prioritizing these industry benchmarks not only ensures compliance but also enhances the overall performance and longevity of your piping systems.

When it comes to the installation and maintenance of polyolefin insulation systems, adherence to best practices is essential for achieving optimal performance and longevity. The first step involves ensuring proper surface preparation before application. Cleaning and drying the surfaces to be insulated helps enhance adhesion and overall insulation efficiency. Furthermore, utilizing the correct thickness of polyolefin insulation, as per project specifications, is crucial to prevent thermal bridging and maintain energy efficiency.

Regular maintenance checks are also vital to sustain the integrity of the polyolefin insulation. Periodic inspections can help identify any signs of wear or damage early on, allowing for timely repairs or replacements. Additionally, it's important to maintain a dry environment, as moisture can compromise the insulation material. By keeping these best practices in mind during installation and maintenance, project managers can achieve superior performance in polyolefin insulation systems, ultimately leading to improved energy efficiency and reduced operational costs.

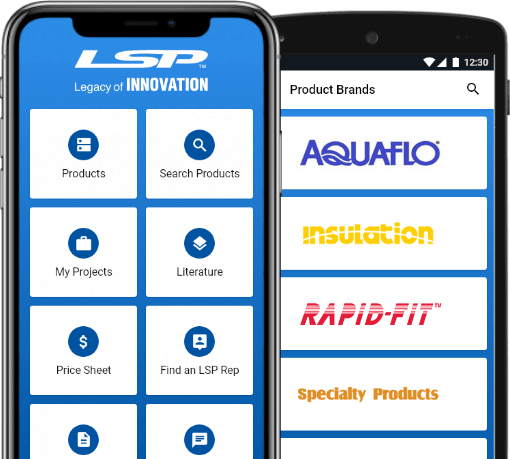

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.