Spray insulation has emerged as a leading solution for homeowners and builders alike, significantly enhancing energy efficiency while offering substantial cost savings. This innovative method involves the application of a special foam that expands upon contact, creating a seamless barrier that effectively minimizes air leaks and heat transfer. As energy costs continue to rise, the demand for effective insulation has surged, making spray insulation a popular choice for those seeking to improve their homes' thermal performance.

The benefits of spray insulation extend beyond mere energy efficiency. Its versatility allows it to be used in various spaces, from attics and walls to crawl spaces, ensuring that even the most challenging areas receive proper insulation. Moreover, the application process is relatively quick and can be completed with minimal disruption to daily life. Choosing the right spray insulation option can make a significant difference in both initial investment and long-term savings, as it contributes to reduced heating and cooling expenses.

In this article, we will explore some of the best spray insulation options available today, focusing on their energy efficiency and cost-saving potential. Whether you are renovating an existing space or constructing a new one, understanding these options can help you make informed decisions that benefit your home and your wallet.

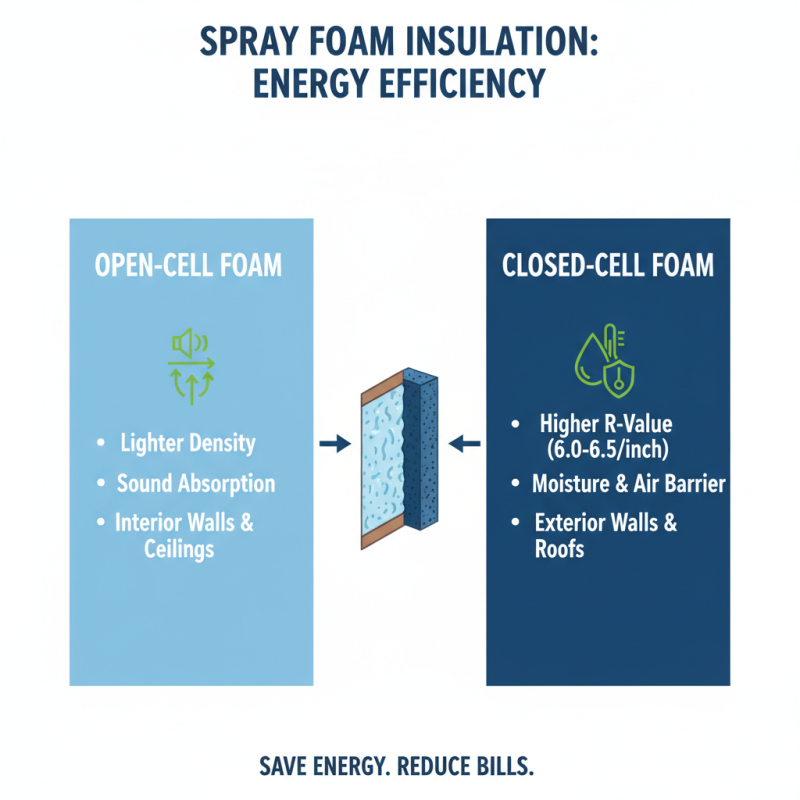

Spray insulation is increasingly recognized for its effectiveness in enhancing energy efficiency within residential and commercial buildings. It primarily comes in two main types: open-cell and closed-cell spray foam. Open-cell spray foam is lighter, allowing for better air circulation and sound absorption, making it ideal for interior applications. Conversely, closed-cell spray foam offers superior insulation value, with an R-value of approximately 6.0 to 6.5 per inch, providing a robust barrier against moisture and air leaks, which is crucial for energy conservation.

The benefits of spray insulation extend beyond mere thermal resistance. According to the U.S. Department of Energy, high-quality insulation can reduce energy costs by up to 30%. Additionally, homes with spray foam insulation benefit from improved indoor air quality, as it minimizes the infiltration of allergens and pollutants. A study by the North American Insulation Manufacturers Association found that even in areas with extreme climates, homes insulated with spray foam experienced significant reductions in energy consumption, further supporting its reputation as a smart investment for homeowners looking to save on heating and cooling costs while creating a healthier living environment.

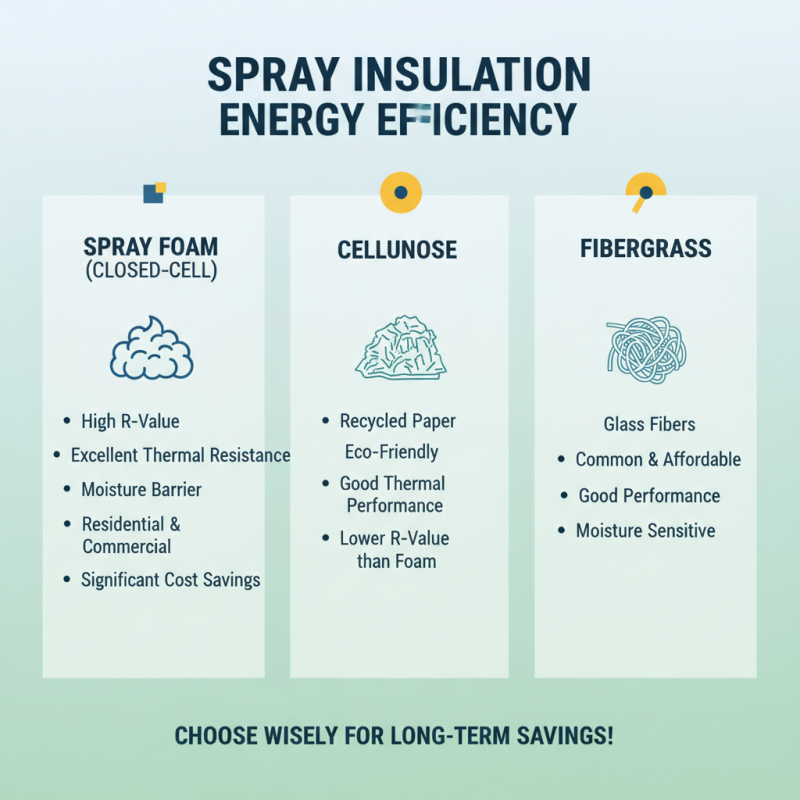

When evaluating energy efficiency in different spray insulation materials, it's essential to understand the varying characteristics each option presents. Common types of spray insulation include spray foam, cellulose, and fiberglass. Spray foam, particularly closed-cell foam, offers high R-values, providing excellent thermal resistance and moisture protection. This makes it suitable for both residential and commercial applications, where energy savings can lead to significant cost reductions over time. On the other hand, cellulose insulation, made from recycled paper, is an eco-friendly alternative that also possesses good thermal performance, though it typically has a lower R-value compared to foam.

When selecting the right insulation material, consider the climate and specific application needs. For instance, in colder regions, higher R-values are more advantageous for maintaining energy efficiency. Conversely, if sustainability is a major factor for you, cellulose might be the better choice. It's also crucial to ensure proper installation since inadequate coverage can lead to thermal bridging and reduced effectiveness.

Tips for maximizing energy efficiency: Always have a professional assess your home’s insulation needs to determine the most suitable material for your situation. Additionally, consider factors like air sealing, which can further enhance the performance of your chosen insulation. Regular checks for any insulation wear or damage can also prevent heat loss and maintain energy savings in the long run.

When evaluating insulation options for energy efficiency and cost savings, the choice between spray foam and traditional insulation materials such as fiberglass or cellulose can significantly impact long-term savings. A recent report by the U.S. Department of Energy outlines that spray foam insulation provides an R-value of around 6 to 7 per inch, which notably outperforms fiberglass batts with an R-value of approximately 3.2 to 4.2 per inch. This enhanced thermal resistance means that properties insulated with spray foam can lead to lower energy bills due to improved heat retention during winter and reduced cooling demands in summer.

Moreover, while the initial installation cost of spray foam can be higher—ranging from $0.90 to $3.00 per board foot—many homeowners find that the investment pays off in the long run. According to the Home Energy Magazine, properties insulated with spray foam can save up to 30% on energy costs annually compared to those using traditional insulation methods. Additionally, spray foam’s airtight seal can prevent air leaks, which are a significant source of energy loss in homes insulated with fiberglass or cellulose, further enhancing its cost-effectiveness over time. Therefore, when assessing insulation options for energy efficiency, spray foam emerges as a leading contender, balancing upfront costs with substantial savings on energy bills.

When it comes to achieving optimal performance from spray insulation, the application techniques you employ can significantly impact energy efficiency and cost savings. First and foremost, ensure that the area to be insulated is clean and free from debris. Proper surface preparation not only promotes adhesion but also guarantees an even application, which is crucial for maximizing thermal resistance. Additionally, working at the right temperature and humidity levels can enhance the curing process, leading to a more effective insulation barrier.

Tips: Always read the manufacturer’s instructions for specific operating conditions and adjust your techniques accordingly. Consider using a moisture meter to ensure that surfaces are adequately dry before application, as excess moisture can compromise insulation integrity.

Another key factor is the correct spray technique. Use a consistent distance from the surface while spraying to create an even layer. This method prevents gaps and ensures that the insulation fills every nook and cranny for maximum efficiency. If necessary, a second pass can be made after the first layer cures to achieve the desired thickness and coverage.

Tips: Practice on scrap materials if possible to master the spraying technique and avoid costly mistakes on your main project. Remember, proper personal protective equipment is a must to ensure safety during the application process.

| Insulation Type | R-Value (per inch) | Cost per Square Foot | Energy Savings Potential | Application Technique |

|---|---|---|---|---|

| Open-Cell Spray Foam | 3.5 - 4.0 | $0.70 - $1.00 | Up to 30% | Quick Set, Requires Protective Gear |

| Closed-Cell Spray Foam | 6.0 - 7.0 | $1.00 - $1.50 | Up to 50% | Professional Application, Longer Cure Time |

| Fiberglass Spray Insulation | 2.9 - 3.5 | $0.40 - $0.75 | Up to 20% | Simple, Can Be DIY Installed |

| Cellulose Spray Insulation | 3.0 - 3.5 | $0.50 - $0.85 | Up to 25% | Blown In, Requires Specialized Equipment |

Spray insulation is an innovative solution that offers significant long-term savings by reducing energy bills, making it an attractive option for homeowners and businesses alike. Unlike traditional insulation, spray insulation creates an airtight seal that minimizes air leaks, ensuring that conditioned air remains within the space. This effectiveness in thermal resistance translates directly into lower heating and cooling costs, as less energy is required to maintain a comfortable indoor environment throughout the year.

Moreover, the long-lasting nature of spray insulation further enhances its cost-saving potential. Once installed, it typically does not need to be replaced or upgraded for many years, leading to reduced maintenance and replacement expenses. Additionally, by promoting a more energy-efficient structure, homeowners may increase their property's value and appeal, not just through immediate energy savings, but by contributing to sustainable living practices.

In essence, investing in spray insulation is not only a smart financial choice but a step towards a more eco-friendly future, as it allows for substantial reductions in energy consumption over time.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.