When considering home improvements, many homeowners are turning their attention to insulation—specifically spray insulation. As energy efficiency becomes increasingly important, understanding the associated costs can be a game-changer. According to insulation industry expert, John Smith, “Investing in high-quality spray insulation can lead to significant savings on energy bills, but it's crucial to grasp the spray insulation cost to maximize your budget.” This highlights the importance of comprehensively analyzing the costs involved.

In 2023, the market for spray insulation continues to evolve, offering various options that cater to diverse needs and preferences. Homeowners are not only seeking to enhance their home’s energy efficiency but are also keen on making informed financial decisions. With a plethora of factors influencing spray insulation cost—including materials, labor, and project size—it's essential to familiarize oneself with these elements. Whether you're considering a full home retrofit or small-scale upgrades, our guide aims to equip you with the knowledge necessary to navigate the complexities of spray insulation pricing effectively.

Spray insulation is an effective solution for homeowners looking to enhance energy efficiency and comfort in their homes. There are primarily two types of spray insulation: open-cell and closed-cell. Open-cell spray foam is lightweight and flexible, ideal for soundproofing and filling gaps in irregular spaces. Conversely, closed-cell spray foam is denser and provides a higher R-value per inch, making it excellent for areas requiring moisture resistance and structural support, such as basements and external walls.

When considering spray insulation, it’s crucial to assess your home’s specific needs. Some tips include evaluating the area you want to insulate and understanding the climate in your region. For example, in colder climates, closed-cell spray foam is typically preferred due to its superior thermal resistance.

Additionally, always consult with a professional to ensure proper installation, as the effectiveness of spray insulation greatly depends on application techniques. Another important factor is the environmental impact of the materials used in spray insulation. Opt for products with low volatile organic compounds (VOCs) to improve indoor air quality.

Furthermore, check for local rebates or incentives for energy-efficient home improvements that may help offset the costs of installation, making it a more budget-friendly option.

When considering spray insulation for your home, understanding the various factors that influence costs is essential. The primary components include the materials used and the labor involved in installation. Spray foam insulation is the most common choice, offering excellent thermal resistance and air sealing capabilities. The type of spray foam—open-cell or closed-cell—can significantly affect the cost, with closed-cell foam generally being more expensive due to its higher density and insulation properties. Additionally, the square footage of the area to be insulated plays a critical role; larger spaces will naturally incur higher material expenses.

Labor costs also contribute to the overall expense of spray insulation. The installation process requires skilled professionals who are trained to handle the chemicals involved safely and effectively. Factors such as geographic location can impact labor rates, with urban areas typically commanding higher prices than rural settings. Moreover, the complexity of the job—such as the need for special equipment or additional safety measures—can further influence labor costs. Homeowners should account for both material and labor when budgeting for spray insulation to ensure they receive a comprehensive understanding of the total investment required.

| Material Type | Cost per Sq. Ft. (Material) | Labor Cost per Sq. Ft. | Total Estimated Cost per Sq. Ft. | R-Value |

|---|---|---|---|---|

| Open Cell Spray Foam | $0.50 | $0.70 | $1.20 | R-3.6 per inch |

| Closed Cell Spray Foam | $1.00 | $0.80 | $1.80 | R-6.0 per inch |

| Fiberglass Insulation | $0.40 | $0.50 | $0.90 | R-2.9 per inch |

| Cellulose Insulation | $0.50 | $0.60 | $1.10 | R-3.5 per inch |

| Mineral Wool Insulation | $0.55 | $0.65 | $1.20 | R-3.7 per inch |

When considering insulation options for your home, it’s crucial to weigh the costs and benefits of spray insulation against alternative materials such as fiberglass, cellulose, and rigid foam. Spray insulation, known for its superior air-sealing properties and energy efficiency, typically comes at a higher upfront cost, with prices ranging from $1.50 to $3.00 per square foot, depending on the thickness and application method. This investment can result in lower energy bills over time, making it an appealing choice for homeowners looking to enhance comfort while reducing heating and cooling costs.

In contrast, alternative insulation options like fiberglass and cellulose tend to be more budget-friendly, often costing between $0.50 and $1.50 per square foot. However, these materials may require additional air-sealing measures to achieve comparable energy efficiency, potentially leading to higher overall installation costs. Rigid foam is another option, offering good thermal resistance but generally operates within a similar price range to spray insulation. Homeowners must consider not only the initial costs but also the long-term savings in energy efficiency when making their decision, ensuring that they choose the best insulation solution for their specific needs and budget.

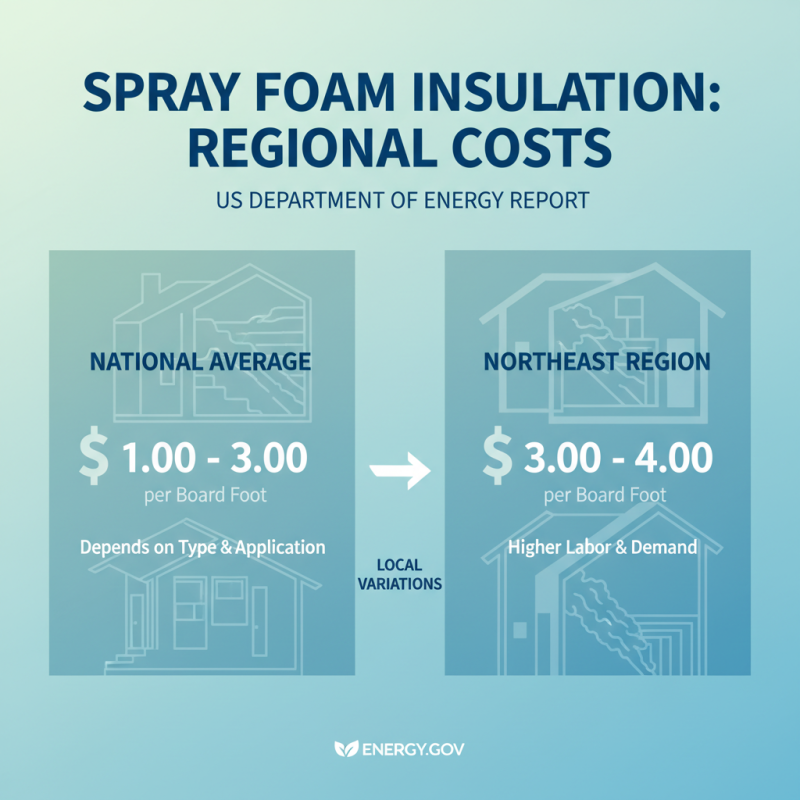

When considering spray insulation, understanding the average installation costs across different regions can significantly impact budgeting for homeowners. According to a report by the U.S. Department of Energy, the average cost of spray foam insulation ranges from $1.00 to $3.00 per board foot, depending on the type and application method. However, these costs can vary widely based on local labor rates and material availability. For instance, homeowners in the Northeast might face higher installation costs, typically around $3.00 to $4.00 per board foot due to increased demand and higher wage standards in the region.

Moreover, regional variations also reflect differences in climate and building codes. In warmer climates, such as the Southeast, where energy efficiency becomes increasingly important, the cost may be lower, averaging about $1.50 to $2.50 per board foot. This is largely due to fewer regulatory barriers and a more competitive market for insulation services. Industry standards also play a role; for example, achieving a high R-value is essential and can influence the choice of insulation system used, ultimately affecting installation prices. Homeowners should consider these regional discrepancies and industry norms when planning their projects to ensure they receive both quality installation and value for their investment.

Investing in spray insulation can lead to significant long-term savings for homeowners, making it a wise choice for those looking to improve their property's energy efficiency. By creating an airtight seal, spray insulation helps to regulate indoor temperatures, reducing the need for constant heating and cooling. This not only cuts energy costs but also contributes to a more comfortable living environment. Over time, these savings can offset the initial installation expense, ultimately providing a solid return on investment.

Moreover, the energy efficiency gained from spray insulation can enhance the overall value of a home. Prospective buyers are often attracted to properties with lower energy bills and increased comfort levels, making insulated homes more marketable. Additionally, many regions offer incentives or rebates for energy-efficient upgrades, which can further mitigate upfront costs. Homeowners who prioritize energy efficiency may find themselves reaping the financial rewards through reduced energy consumption and increased home equity, underscoring the long-term benefits of choosing spray insulation.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.