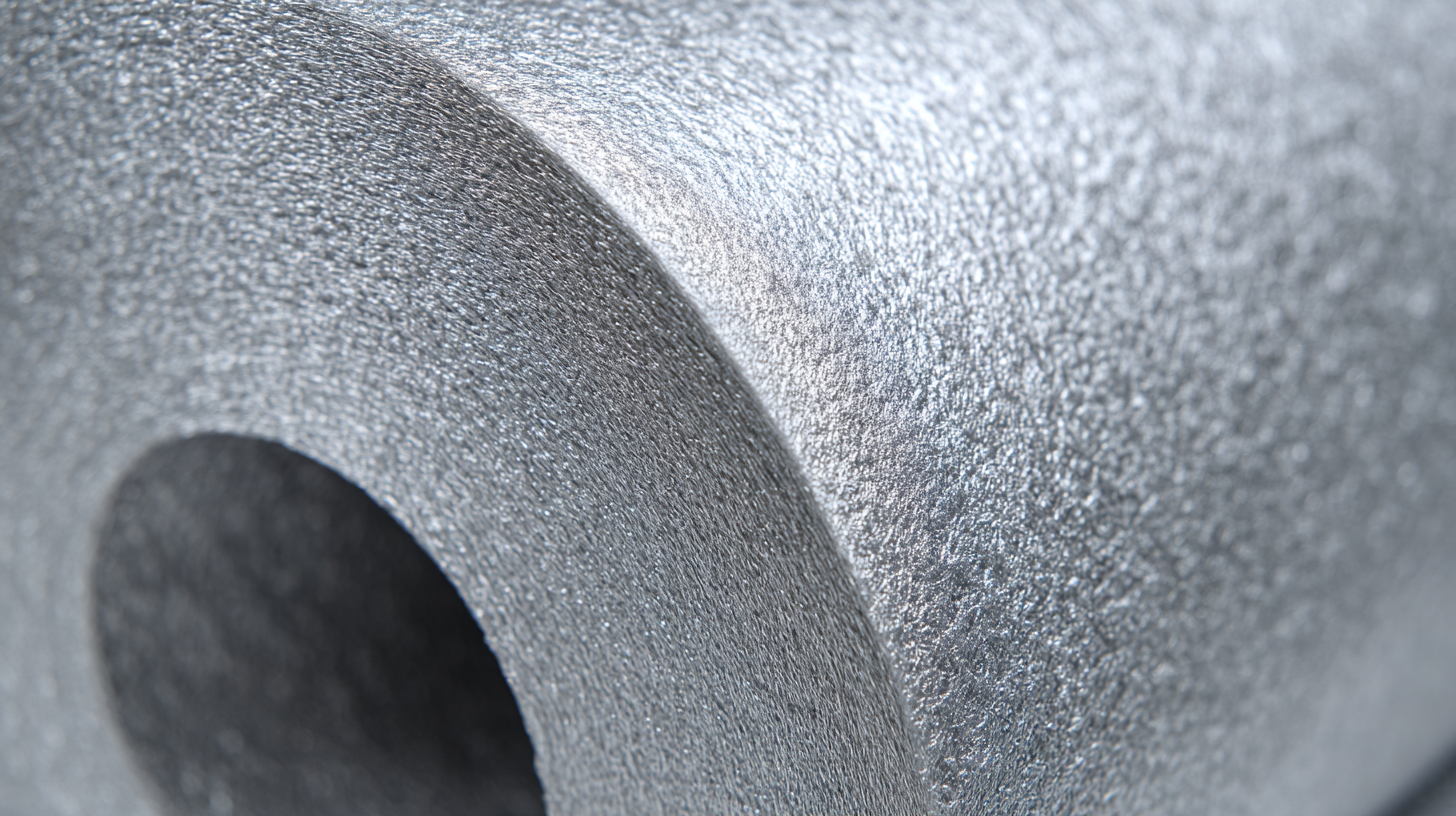

In the pursuit of energy efficiency and sustainability, the building and construction industries are increasingly turning to innovative materials that meet both environmental and performance standards. Among these materials, the polyolefin insulation sheet stands out due to its remarkable properties. Engineered from thermoplastic polymers, polyolefin insulation sheets provide exceptional thermal resistance, moisture control, and durability, making them ideal for a variety of applications.

Their lightweight nature not only facilitates ease of installation but also contributes to reducing transportation emissions, aligning with sustainability goals. Additionally, polyolefin insulation sheets are often recyclable, further enhancing their appeal in environmentally conscious projects. This article will delve into the numerous benefits of polyolefin insulation sheets, exploring their role in promoting energy efficiency and fostering a more sustainable future in construction practices.

Their lightweight nature not only facilitates ease of installation but also contributes to reducing transportation emissions, aligning with sustainability goals. Additionally, polyolefin insulation sheets are often recyclable, further enhancing their appeal in environmentally conscious projects. This article will delve into the numerous benefits of polyolefin insulation sheets, exploring their role in promoting energy efficiency and fostering a more sustainable future in construction practices.

Polyolefin insulation sheets are gaining attention for their role in enhancing energy efficiency and promoting sustainability. These sheets are typically made from polyolefin materials such as polyethylene and polypropylene, which are known for their excellent thermal performance. Unlike traditional insulation materials, polyolefin sheets offer a unique combination of light weight, flexibility, and moisture resistance, making them ideal for a wide range of applications, from building insulation to HVAC systems.

Polyolefin insulation sheets are gaining attention for their role in enhancing energy efficiency and promoting sustainability. These sheets are typically made from polyolefin materials such as polyethylene and polypropylene, which are known for their excellent thermal performance. Unlike traditional insulation materials, polyolefin sheets offer a unique combination of light weight, flexibility, and moisture resistance, making them ideal for a wide range of applications, from building insulation to HVAC systems.

Tips for selecting the right polyolefin insulation sheets include checking their R-value, which indicates thermal resistance. Higher R-values signify better insulation performance. Additionally, consider the environmental impact by choosing products with recycled content or certifications like GREENGUARD, which ensure reduced chemical emissions.

When installing polyolefin insulation sheets, keep in mind that a well-sealed application is crucial for maximizing energy efficiency. Properly sealing the joints and edges can prevent air leaks, improving overall insulation effectiveness. Also, ensure that the installation environment is dry to prevent moisture-related issues, which can compromise the integrity of the insulation.

Polyolefin insulation sheets have emerged as a significant material in enhancing energy efficiency across various applications. These sheets, made from polymers like polyethylene and polypropylene, offer superior thermal resistance, thereby reducing heat transfer in buildings and industrial settings. This characteristic plays a crucial role in maintaining desired temperatures, leading to reduced reliance on heating and cooling systems. Consequently, energy consumption is lowered, which not only slashes utility bills but also contributes to a decrease in greenhouse gas emissions.

Moreover, the lightweight nature and durability of polyolefin insulation sheets facilitate easier installation compared to traditional insulation materials. Their resistance to moisture and chemicals further enhances their longevity, minimizing the need for frequent replacements. This durability indicates a reduced environmental impact, aligning with sustainability goals. As more industries and consumers seek eco-friendly solutions, the integration of polyolefin insulation becomes a proactive step towards energy efficiency.

Polyolefin materials, including insulation sheets, have emerged as front-runners in promoting environmental sustainability within the construction industry. According to the "2022 Global Insulation Market Report," polyolefin insulation products demonstrate a lower environmental impact compared to traditional insulation materials, with up to 30% lower greenhouse gas emissions during production. This is primarily due to the efficient manufacturing processes and the inherent properties of polyolefin, which allow for reduced energy consumption throughout their lifecycle.

Furthermore, polyolefin insulation sheets are recyclable and contribute to a circular economy. A study by the International Association for Research and Testing in Construction Materials (IARTCM) indicates that nearly 90% of polyolefin materials can be reprocessed after their initial use. This ability to recycle not only reduces landfilling but also aligns with global sustainability goals by minimizing resource extraction and waste. By choosing polyolefin insulation, builders and consumers can significantly lower their carbon footprints while benefiting from superior energy efficiency, making them a practical choice for environmentally-conscious projects.

This chart illustrates the impact of polyolefin insulation sheets on energy savings and environmental sustainability. The data represents the percentage of energy savings and reduction in carbon emissions when using polyolefin materials in construction compared to traditional insulation materials.

When installing polyolefin insulation sheets, proper adherence to guidelines can significantly enhance their performance and energy efficiency. According to a report by the U.S. Department of Energy, effective insulation can reduce heating and cooling costs by up to 50%. This underscores the importance of ensuring that insulation sheets are applied correctly to maximize thermal resistance. Proper surface preparation, for example, is crucial; surfaces must be clean, dry, and free of contaminants to enable optimal adhesion and function.

Additionally, it is recommended to use appropriate sealants and tape around seams to prevent air leakage, which can diminish the insulating properties of the sheets. The National Renewable Energy Laboratory (NREL) emphasizes that even small gaps can lead to energy losses of up to 20%. To further enhance energy savings, installers should consider factors such as local climate and building orientation – adjustments in the thickness of the insulation can lead to a significant uplift in performance. These installation best practices can transform buildings not only into energy-efficient structures but also into more sustainable environments, aligning with contemporary green building standards.

| Dimension | Description | Benefits | Installation Guidelines |

|---|---|---|---|

| Thickness | Available in various thicknesses for different insulation needs. | Improved thermal performance and energy savings. | Ensure proper sealing and overlaps during installation. |

| R-Value | The measure of thermal resistance provided by insulation. | Higher R-values indicate better energy efficiency. | Select R-value based on climate and application. |

| Moisture Resistance | Resistant to moisture, preventing mold and decay. | Enhances indoor air quality and longevity of materials. | Install in dry conditions to maintain effectiveness. |

| Sustainability | Made from environmentally friendly materials. | Reduces carbon footprint and promotes energy conservation. | Adhere to local building codes for sustainable installation. |

Polyolefin insulation sheets have gained attention as a sustainable alternative to traditional insulation materials such as fiberglass and foam. Unlike conventional options that often contain harmful chemicals and face challenges regarding disposal, polyolefin offers a more environmentally friendly profile. Derived from natural polymer sources, these sheets are not only lightweight but also exhibit excellent thermal resistance, reducing energy consumption in buildings and contributing significantly to overall energy efficiency.

In terms of performance, polyolefin insulation demonstrates exceptional moisture resistance, which helps prevent mold and mildew growth, a common issue with traditional materials. This durability ensures a longer lifespan and lower maintenance costs over time. Additionally, polyolefin sheets can be easily recycled, aligning with modern sustainability goals. Their ability to provide effective insulation while minimizing environmental impact makes them a compelling choice for architects and builders looking to enhance energy efficiency in their projects.

Scan QR code to download the app

LSP Products was founded by plumbers over 50 years ago with a focus on unparalleled innovation, superior product quality, and best-in-class service to the plumbing industry. Our primary focus is the new construction market where we develop products that make installations easy and provide significant cost savings to the plumbing/mechanical contractor. LSP has a manufacturing facility located in Monterrey, Mexico and a distribution center in Dallas, Texas. We are proud to offer many products designed and made in North America… About LSP

Submit the form below to receive the document via email.